Project Description

Flow rate 0.39 to 1.64 mÑ/min, Pressure 5.5 to 15 bar

Long-term savings

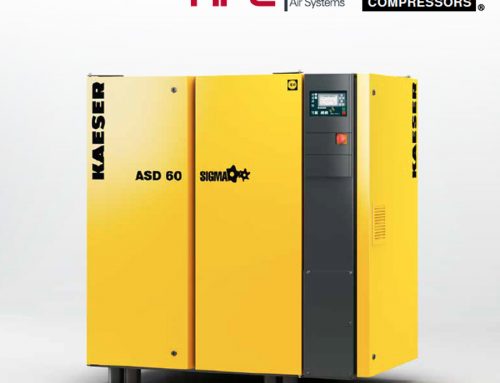

Discerning compressed air users expect maximum availability and efficiency even from smaller compressors. It will come as no surprise therefore that KAESER’s SM series rotary screw compressors go far beyond meeting these key expectations. Not only do they deliver more compressed air for less energy, but they also combine ease of use and maintenance friendliness with exceptional versatility and environmentally responsible design.

SMart with SIGMA 06

The latest generation SM series rotary screw compressors feature the new SIGMA 06 airend with further-refined SIGMA PROFILE rotors for even greater intake volume and efficiency. The result? Up to 13 percent reduced energy requirement and up to 10 percent higher flow rate.

Energy-saving performance

The efficiency of a machine depends on the total costs incurred throughout the equipment’s entire service life. With compressors, energy costs account for the lion’s share of total expenditure. KAESER therefore designed its SM series compressors with optimum energy efficiency in mind. Refinements to the energy-saving SIGMA PROFILE airend rotors and the use of Super Premium Efficiency IE4 motors (Premium Efficiency IE3 motor in the SM 10) have significantly contributed to the increased performance of these versatile compressors. The combination of the SIGMA CONTROL 2 internal controller, low airend speeds, minimised internal pressure losses and KAESER’s unique cooling system has helped to push the boundaries of efficiency even further.

Optimised design

The new SM models all share logical and user-friendly design throughout. For example, the left-hand side panel can be removed in a few simple steps and allows excellent visibility of the system’s intelligently laid out components – moreover, all maintenance points are easily accessible. When closed, the sound-absorbing compressor enclosure keeps operational sound levels to a minimum thereby ensuring a pleasantly quiet work environment. In addition, the enclosure features four inlet openings for separate airflow cooling of the compressor, the motor, the control cabinet and the compressor intake air. Last, but not least, SM series compressors are impressively compact, which makes them the perfect choice for applications where space is at a premium.

Modular system concept

SM series compressors are available as standard versions, as so-called “T” models (equipped with an integrated, thermally shielded refrigeration dryer) and as “AIRCENTER” models that additionally include an under-slung air receiver. KAESER’s intelligent modular design therefore offers incredible flexibility. Moreover, the SM 13 model is also available with an integrated frequency converter for infinitely-adjustable flow rate control.

Why choose heat recovery?

The question should in fact be: Why not? Amazingly, up to 100 % of the (electrical) energy input to a compressor is converted into heat. Up to 96 % of this energy can be recovered and reused for heating purposes. This not only reduces primary energy consumption, but also improves the applicable company’s total energy balance

Let’s Connect

Call or email one of our friendly experts for more information